Let’s Talk About Your Specific Needs

At Rutpen we have a highly experienced team of chemical specialists, with knowledge developed from over 50 years of operating in this industry. Our large and diverse client base has been grown from a desire to solve complex chemical-related problems.

Our skills are right across our core areas of Contract Manufacturing, Toll Blending and Solvent Recycling, including: technical development, manufacturing, warehousing and logistics.

How We Can Help You

-

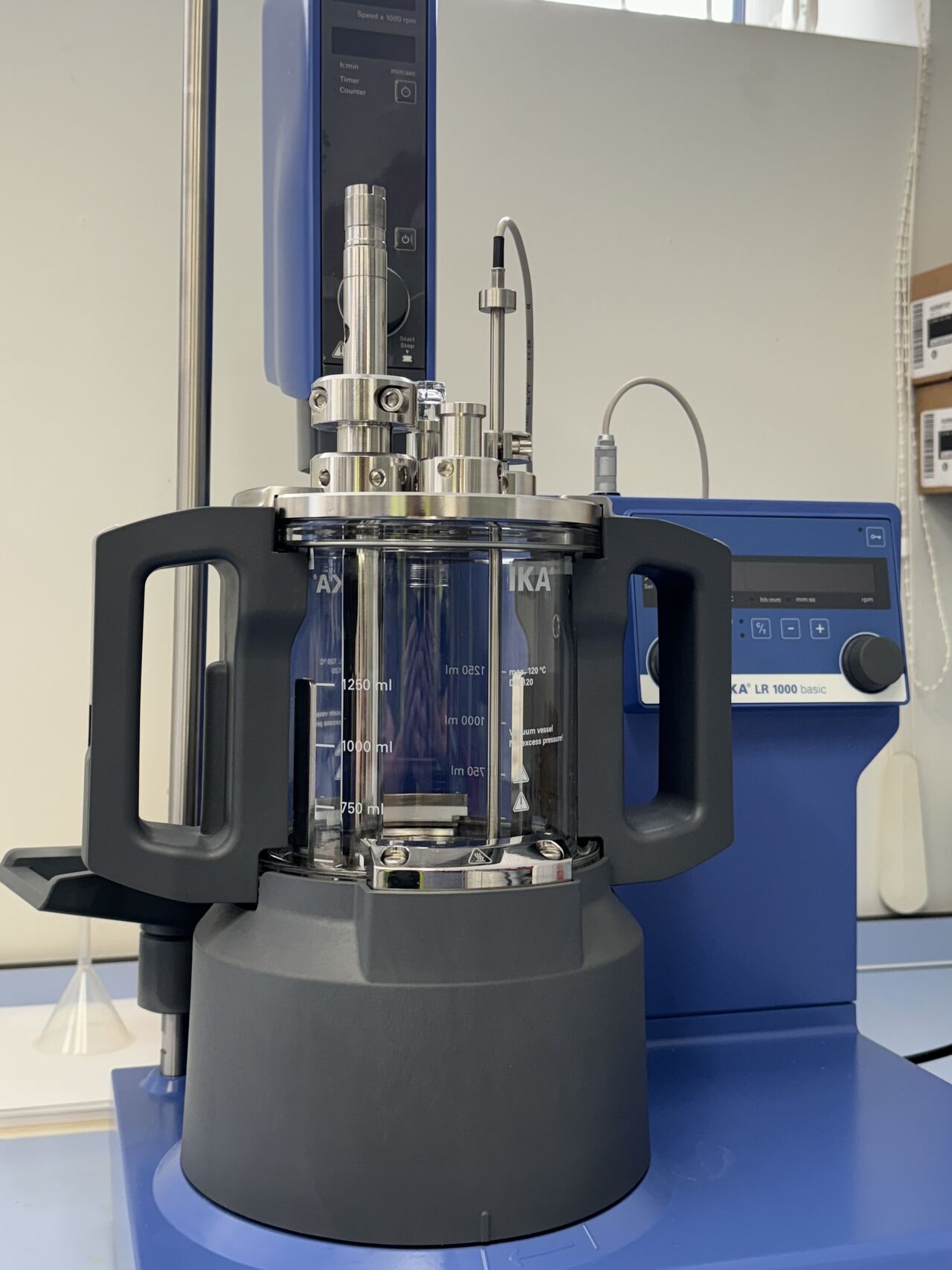

Liquid Blending

Find Out More >With over 50 mixing vessels across our site for liquids or powders with a range of capabilities such as heating and cooling we can produce in excess of 60,000L per day.

-

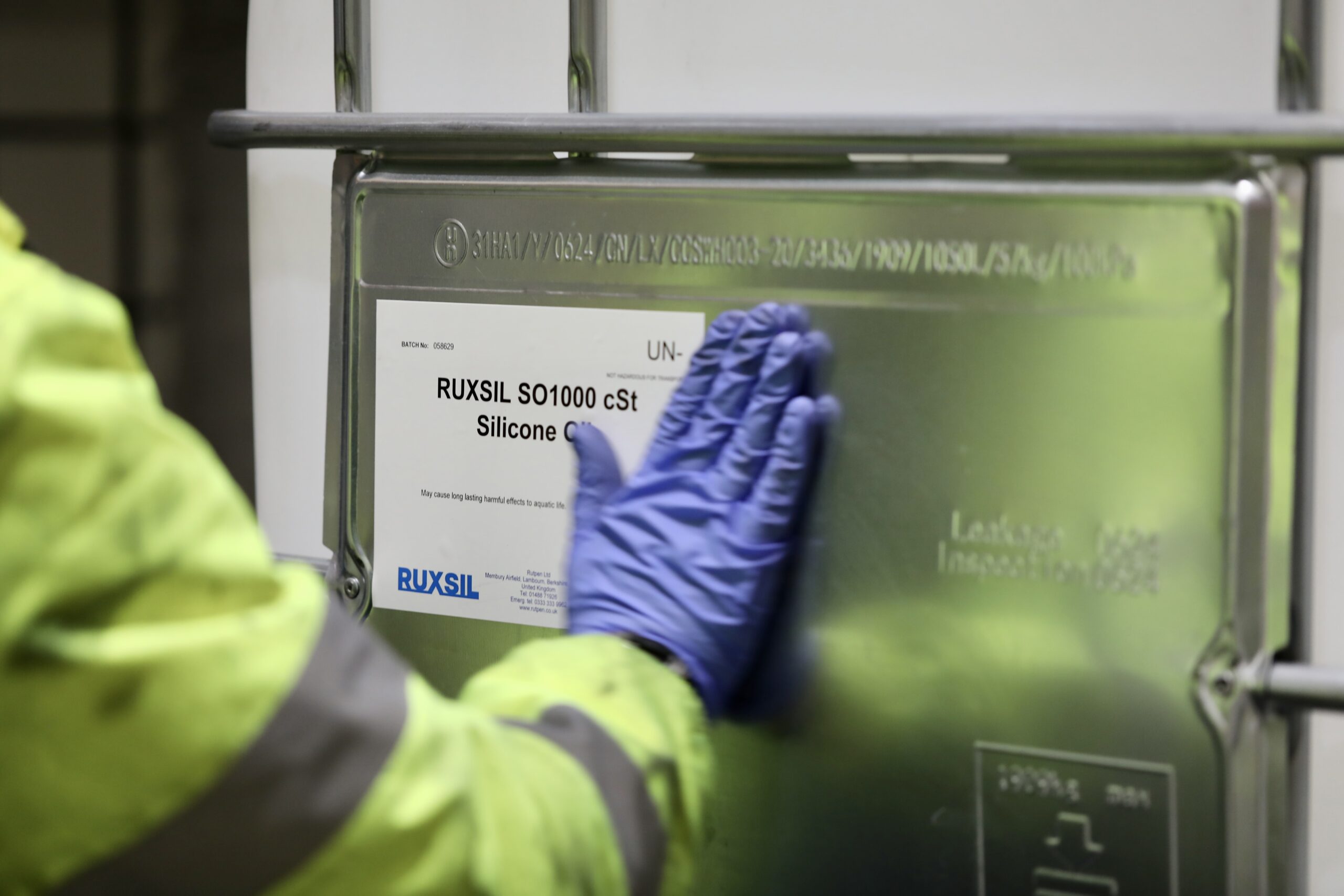

Silicone Division

Find Out More >The Ruxsil team brings Rutpen’s outstanding reputation and capabilities directly to a wide range of industries offering an efficient and comprehensive supply chain.

-

Contract Manufacturing

Find Out More >Inside our purpose-built production facility, we have 6 automated filling and labelling lines to manufacture your products. We also have a wide variety of versatile filling, packing and labelling machines to suit your requirements.

-

Solvent Recovery & Blending

Find Out More >We are experts in the field of solvent recovery and our extensive solvent recycling facility has an environmental permit and is regulated by the Environment Agency.

Your Trusted Partner

-

ISO Accredited

We have a long standing commitment to quality management, gaining our first accreditation in 1987. We currently hold ISO 9001, ISO 14001 and ISO 45001 accreditations covering quality, environment and occupational health & safety.

-

Environmental

We are committed as a responsible business to take care of our local environment on our manufacturing site and in our environmental footprint. This includes making every effort to take account of the environment in our decision making, as well as investing in appropriate facilities whenever possible.

-

Confidential

To ensure that there is no conflict of interests with our toll blending customers, Rutpen acts as a chemical blending service offering a high level of confidentiality to customers. Rutpen has built a reputation for confidentiality as well as service, quality and cost.

-

Independent

We are proud to be independent and provide the chemical industry with a high quality, confidential service without compromise. With a reputation for fast innovative service, exceptional client relationships with guaranteed confidentiality has made us one of the UK’s leading independent chemical manufacturers.

-

Established

Rutpen Ltd was established in 1970, originally to supply small pack solvents to industry. Sustained investment in premises and plant, and recruitment of highly qualified and experienced chemists and engineers over the ensuing years has developed Rutpen into today’s multi-million pound, industry leading company.

-

Trusted

Our skills are right across our core areas of Contract Manufacturing, Toll Blending and Solvent Recycling, including: technical, manufacturing, warehousing and logistics. This is all underpinned with a strong belief in quality management, great service, the importance of confidentiality and a genuine care for our impact on the environment.

Find Out More About Our Capabilities

What We've Been Up To Recently

Just Some Of Our Trusted Customers

“Following a factory fire, the original client needed a new manufacturing plant – and fast – for the manufacture of domestic / retail wood treatment products. This emergency response was a complex project due to the low flashpoint of the products and the need to produce a retail-quality product.”2022

“The client is a manufacturer of silicone base ingredients for use in cosmetics and industrial applications, but its headquarters are not based in the UK and its UK plant is not conducive to the manufacture of highly flammable materials.”2021

“An existing client wanted to upgrade one of their UK based facilities that provided chemicals in bulk for the food and brewing sectors, but needed to continue servicing their clients while the engineering work was underway.”2021

“During Tube Store retrieval operations at it’s site, the client became aware of accumulations of contaminated water residing in some of the tubes. This was a complex and programme critical project that required an innovative solution.”2022

“As a manufacturer of printing inks, the client handles a number of solvents on site to clean the equipment between products and needs to ensure that there is no contamination. It then must manage this waste product in the most environmentally-friendly manner.”2022

“The client prints designs on t-shirts and uses a liquid conditioner to cure inks within the printing process. The original supplier of the conditioner (and manufacturer of the equipment) was overseas and the local agent ceased supply to the UK, resulting in a cost and continuity issue, so the brief from the client was to develop an alternative liquid”2022

“Solvent is used in automotive factories to clean the robot paint machines between different coloured paint sprays, which can be as frequently as every few minutes. This means that there is a huge volume of solvent that needs to be recovered regularly.”2022